الحار منتجات

ملكنا الإخبارية

comthickener of magnetic separator for iron or

Development of a centrifugal dry magnetic separator for

2024/3/15 1. Introduction. In arid and severely cold regions such as west China, a plenty of iron ores are difficult to be economically utilized due to water scarcity [1, 2], so

获取价格

Magnetic separation: A review of principles, devices, and

Conventional magnetic separation devices are widely used for the removal of tramp iron from a variety of feed materials and for the beneficiation of ferrous ores. These devices

获取价格

Chapter 2 Magnetic Separation - Springer

32 2 Magnetic Separation Fig. 2.2 Classification of magnetic separators from different perspectives [14]. Re-drawn figure Dry low-intensity magnetic separators (DLIMS) are

获取价格

Iron ore tailings valorization through separate ... - Springer

Simplified flowsheet of the studied iron ore processing plant and the sampling locations (T1:

Wet High-Intensity Magnetic Separators (WHIMS) for Recovering

2019/10/3 The material contains approximately 30% of the iron, and recovering this iron is important in decreasing the environmental impact and increasing production. The

获取价格

Mineral Magnetic Modification of Fine Iron Ore Tailings and

After magnetic separation, the magnetic con-centrates consisted almost completely of magnetite (with the magnetization of 75–88 Am2/kg) and non-magnetic residues

获取价格

Minerals Free Full-Text Dry Permanent Magnetic

2022/9/9 The industrial test results of this magnetic separator reveal that the iron grade improved by 9.3 percentage points and that the recovery rate reached 90.85% after primary sorting using <1 mm KBH

获取价格

Wet low intensity magnetic separators - Metso

et versions to the iron ore industry.Metso has (in close co-operation with the iron ore mining Industry) developed and designed the low intensity magnetic separators to meet the

获取价格

Physical separation of iron ore: magnetic separation - ScienceDirect

2022/1/1 Low-grade iron ore mined from the earth is usually composed of several minerals, desirable and undesirable. Magnetic separation means applying a magnetic

获取价格

Low Intensity Dry Drum Magnetic Separator - JXSC

Dry Drum Magnetic separator is one of the most widely used and versatile machines in mineral processing. Mineral technologies electrostatic separators suitable for manganese ore, magnetite, pyrrhotite, roasting

获取价格

Magnetic Ore - an overview ScienceDirect Topics

Anshan type lean hematite ore, located in Anshan area of northeast China, is one of the mostly typical iron ores of super-large reserve. In the past, this low-grade iron ore was crushed and classified into coarse and fine fractions, with the coarse fraction reductively roasted and the fine fraction processed in a gravity-high-intensity magnetic separation

获取价格

High Intensity Magnetic Separator - JXSC Machinery

High-intensity magnetic separators, or multi-roller magnetic separators, are iron removal/magnetic separation equipment for sorting weak magnetic minerals.It is widely used in limonite, manganese ore, and

获取价格

IRON ORE BENEFICIATION - Multotec

TYPICAL IRON ORE BENEFICIATION FLOW SHEET Fine Product Effluent Pump Dewatering Screen Static Screen Panels Floats Drain Rinse Screen Gyratory Crusher ROM Stockpile Sizing Screen Sizing Screen Spirals Thickener Magnetic Separator Medium Densification Cyclone Over Dense Medium Sinks Drain Rinse Screen Coarse DMS

获取价格

Application Of Superconducting High Gradient Magnetic Separation ...

2017/5/17 ABSTRACT. Comprehensive utilization of tailings resources not only solves environmental problems but also creates huge economic benefits. In this paper, fine weakly magnetic particles were extracted from iron ore beneficiation tailings and silica (SiO 2) was separated and purified using a superconducting high gradient magnetic

获取价格

Heavy Media Separation Process - 911 Metallurgist

2016/5/22 The Sink and Float separation process is part of what is also known as a Heavy Media Separation Process (HMS) and are commercial adaptations of the common laboratory procedure used for separating a mixture of two products having differentials in specific gravity by immersing the sample in a heavy liquid having a gravity intermediate

获取价格

Intensity Magnetic Separator - an overview ScienceDirect Topics

As shown in Figure 13.2, minerals with ferromagnetic properties have high susceptibility at low applied field strengths and can therefore be concentrated in low intensity (<~0.3 T) magnetic separators. For low-intensity drum separators (Figure 13.11) used in the iron ore industry, the standard field, for a separator with ferrite-based magnets, is 0.12 T at a

获取价格

Feasibility study of iron ore fines beneficiation by shallow bed air ...

2020/3/25 Magnetic separation, dense media suspension fluidization techniques are tested for dry beneficiation of iron ore fines presently and found to have limitations. In the present study, the potential of shallow bed air fluidized separator (SBAFS), which does not have any suspension media and has high throughput is investigated for iron ore fines ...

获取价格

STEINERT MRB for two-stage magnetic separation of ferrous

Our two-stage magnetic separator therefore combines a STEINERT MTP extracting magnetic drum with a STEINERT MSB traversing magnetic pulley. Whilst the former generates valuable scrap iron, the magnetic pulley in the second stage separates weakly magnetic components that represent impurities in downstream processes and can have

获取价格

Three Disc Dry Magnetic Separator - JXSC Machine

Three Disc Dry Magnetic Separator 【Capacity】100-500 Kg/H 【Feeding Size】≤2mm 【Type】3PC-500, 3PC-600, final process of heavy mineral concentrate, improve the grade. 【Application】Dry magnetic separations of ilmenite, rare earth ore, chromite, tungsten and tin ores, limonite, columbium and tantalum ores, zircon, rutile, monazite, andalusite,

获取价格

Physical separation of iron ore: magnetic separation

2022/1/1 This chapter introduces the principle of how low-grade iron ores are upgraded to high quality iron ore concentrates by magnetic separation. Magnetite is the most magnetic of all the naturally occurring minerals on earth and can be readily extracted by low-intensity magnetic separators from magnetite ores. On the other hand, oxidized

获取价格

Nickel Ore Beneficiation Plant - JXSC Machinery - Mineral Processing

Nickel ores mainly include copper-nickel sulfide ore and nickel oxide ore (laterite nickel ore). The most important is the nickel ore flotation process, magnetic separation and gravity separation are usually auxiliary beneficiation methods.. We can customize nickel ore beneficiation process and equipment to achieve comprehensive utilization of resources

获取价格

Wet low intensity magnetic separators - Metso

Wet low intensity magnetic separators Iron ore processing General Metso has produced several thousand Low In-tensity magnetic separators (LIMS) both dry and wet versions to the iron ore industry. ... Iron ore separation 8 000 – (15 000) 100 – 160 200 – 350 Concurrent Coarse (Cobbing) 0 – 10% Counter-rotation ...

获取价格

8 Types of Iron Ore Magnetic Separator - Mining-pedia

2022/3/25 Magnetic separation is the most common process in iron ore processing plant. Due to the difference in ore properties, the magnetic separation methods in actual production are also different, so different magnetic separators are also used. This article will introduce 8 common magnetic separators to you.

获取价格

Physical separation of iron ore: magnetic separation

2022/1/1 This chapter introduces the principle of how low-grade iron ores are upgraded to high quality iron ore concentrates by magnetic separation. Magnetite is the most magnetic of all the naturally occurring minerals on earth and can be readily extracted by low-intensity magnetic separators from magnetite ores. On the other hand, oxidized

获取价格

Nickel Ore Beneficiation Plant - JXSC Machinery

Nickel ores mainly include copper-nickel sulfide ore and nickel oxide ore (laterite nickel ore). The most important is the nickel ore flotation process, magnetic separation and gravity separation are usually auxiliary

获取价格

Wet low intensity magnetic separators - Metso

Wet low intensity magnetic separators Iron ore processing General Metso has produced several thousand Low In-tensity magnetic separators (LIMS) both dry and wet versions to the iron ore industry. ... Iron ore separation 8 000 – (15 000) 100 – 160 200 – 350 Concurrent Coarse (Cobbing) 0 – 10% Counter-rotation ...

获取价格

8 Types of Iron Ore Magnetic Separator - Mining-pedia

2022/3/25 Magnetic separation is the most common process in iron ore processing plant. Due to the difference in ore properties, the magnetic separation methods in actual production are also different, so different magnetic separators are also used. This article will introduce 8 common magnetic separators to you.

获取价格

Dense Media Separation (DMS) Plants - JXSC Machine

In a Dense Media Separation (DMS)/ Heavy Media Separation( HMS) plant, powdered ferrosilicon (an alloy of iron and silicone) is suspended in water to form a fluid near the density of diamond (3.52 g/cm3), to which the diamond-bearing material is added to begin the separation process of the heavier minerals from the lighter material.

获取价格

Mineral Jig Separator Jig Concentrator - JXSC Machinery

Jig separator (jig concentrator, jig machine) is a equipment that drives pulses of water upwards through a thick bed of settled sediment to keep it loose and agitated.This achieves gravitational separation by allowing the denser minerals to sink easily and quickly through the lighter minerals. Jig separator are widely used in various heavy metal, metallic and

获取价格

Column thickener and a process thereof for dewatering of iron

Magnetic separation, method and apparatus US4034667A (en) * 1974-10-10: 1977-07-12: Cartwright Vern W: Hot stamping machine with rotatable head ... Developments in the physical separation of iron ore: magnetic separation: Rocha et al. 2010: Iron ore slimes flotation: CN106914337B (en) 2022-08-26:

获取价格

Types of Mining Magnetic Separators - Mineral Processing

2024/8/14 Wet Permanent Magnetic Drum separator is a kind of magnetic separator often used in iron ore concentrators. It is suitable for separating high magnetic minerals. According to the different structure of the tank, it can be divided into three types: downstream type, counter-current type, and semi-counter-current type. ...

获取价格

Iron Ore Beneficiation Plant - JXSC Machinery - Mineral Processing

Materials over 5mm are sieved and returned to the double-roll crusher for further processing. Those under the sieve under 5mm material are sent to the first and second magnetic separators. 5. The output from the first and second magnetic separators will be sent to the third magnetic separator to separate the iron ore again. Finally, the iron ...

获取价格

A Comprehensive Guide to the Operation of Thickener Mining

2023/10/28 The operation of a mining thickener involves several fundamental principles: 1. Gravity Settling. Mining thickeners rely on the force of gravity to promote the settling of solid particles within the thickener tank.

获取价格

Beginners guide to thickeners - Metso

2017/6/16 Thickening is a process where a slurry or solid-liquid mixture is separated to a dense slurry containing most of the solids and an overflow of essentially clear water (or liquor in leaching processes). The driving force for the separation is gravitational, where the differences in phase densities drive the separation of the solids and liquid.

获取价格

DRY MAGNETIC SEPARATION OF MAGNETITE ORES ScienceGate

The study of beneficiation indicators of the magnetic separator was carried out using iron ore of the Bapy deposit, which is mono-mineral magnetite. For the study, mixtures of the minus 0.1 mm class were selected with the iron content α = 50% and α = 40%. As a result of the research, beneficiation indicators were obtained on a laboratory scale.

获取价格

Iron Separator, Magnetic Stirrer, Magnetic Separator - Huate

With more than 30 years experience in the RD of magnetic separation technologies, we specialize in manufacturing superconducting magnetic separators, electromagnetic wet dry high intensity magnetic separators, permenant wet dry magnetic separators, overhead magnetic iron separators, eddy current separators, ultra-fine grinding and

获取价格

Improve Mineral Processing Efficiency By Magnetic Separator

2024/8/14 Magnetic separator is the basic tool used by mineral processing plants to separate ferrous and non-ferrous metals from extracted ore, ensuring high-quality final products. Its works by attracting magnetic particles such as iron, steel and nickel, and then using powerful magnets or electromagnets to separate these particles from other materials.

获取价格خطة التعدين لتكسير محجر الحجر

مصنع مسحوق البازلت

آب سرباره تولید کنندگان ماشین آلات پردازش

تفضيلات كسارة الفك كسارة GRAFIK

كربونات الكالسيوم الحزام الناقل

سنگ شکن تست عملکرد

سحق نيتريد البورون

معالجة خام الذهب المصنع المملكة العربية السعودية

آلة كسارة جبل المسار

كسارات رائدة

cmi cmi jaw crusher model

التكنولوجيا الجديدة منتجات الصين كسارة الحجر الإجمالية

مورد آلة صانع الرمل في كندا

الفك محطم كفاءة مواد البناء

سحق طحن سبودومين في جنوب أفريقيا

معدات لتعدين الذهب جنوب أفريقيا

عينات الصخور سحق في نيجيريا

الشاشة تهتز ميلا في الغالون

محطم كسارة متنقلة باتوبارا

مصانع خلط الخرسانة الجاهزة

محطم تبديل الفك أوروبا

تأجير المعدات سيدني

تعدين الرمل في مصر

موردو محطات التكسير في الإمارات العربية المتحدة

بلاسر الذهب غسل النبات 200 ياردة في الساعة

تعدين الأسبستوس في أفريقيا

حول لدينا

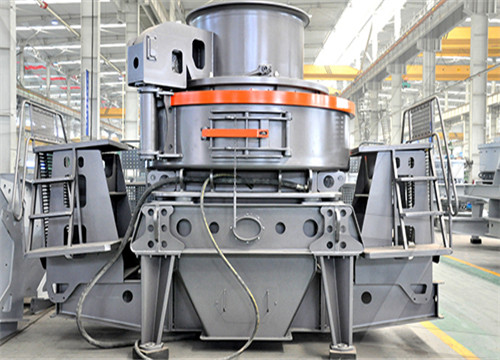

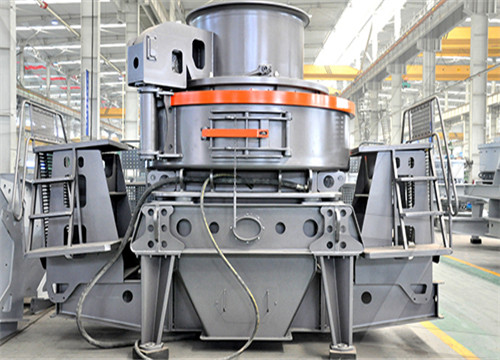

تأسست شركة Henan Lrate للعلوم والتكنولوجيا المحدودة التي تصنع معدات التكسير والطحن الكبيرة والمتوسطة الحجم في عام 1987. وهي شركة مساهمة حديثة مع البحث والتصنيع والمبيعات معًا.

على مدار أكثر من 30 عامًا ، تلتزم شركتنا بنظام الإدارة العلمية الحديث والتصنيع الدقيق والريادة والابتكار. الآن أصبحت LIMING رائدة في صناعة تصنيع الآلات المحلية والخارجية.

2021/07/20

2021/07/20