الحار منتجات

ملكنا الإخبارية

ironsand beneficiation

Titaniferous Magnetites as a Source of Vanadium, Titanium

For transition and primary hard rock ores, beneficiation produces clean concentrates for further processing. 2 Table 1: Mineralogy of titanium-bearing minerals Mineral Formula TiO ... The primary function of the kiln is to remove oxygen from the iron sand to produce a

获取价格

Beneficiation of Kulon Progo iron sand by using tabling and

2018/4/3 Therefore, the proper beneficiation methods are need to improve the iron content of iron sand. In this research Kulon Progo iron sand was used as a raw

获取价格

Ironsand (Titanomagnetite-Titanohematite): Chemistry, Magnetic ...

2021/9/21 Ironsand is an abundant and inexpensive magnetic mineral resource. However, the magnetic properties of unprocessed ironsand are often inadequate for any

获取价格

Beneficiation of Kulon Progo iron sand by using tabling and

2018/4/3 On the other and, iron sand is rarely used as a raw material because the iron content is low (20-40%) but the iron sand reserves are very abundant in Indonesia

获取价格

Advancing Iron Ore Beneficiation: Exploring Cutting-Edge

May 1, 2024. In the dynamic landscape of mining and metallurgy, the iron ore beneficiation process stands as a cornerstone, pivotal in transforming raw ore into high-grade iron

获取价格

Beneficiation of Kulon Progo iron sand by using tabling and

There are two types of iron resources such as primary iron ore and iron sand. In general, primary iron ores use as raw materials in iron and steel making because the iron content

获取价格

INDUSTRIAL MINERALOGY: MINERAL PROCESSING,

broad beneficiation techniques of different minerals are discussed in this chapter which will help to comprehend the potentiality of minerals in the realm of industrialization. 17.1

获取价格

Towards a Sustainable and Enhanced Iron Ore Recovery: Bio

2024/3/16 Iron ore is essential in steel making; however, high-grade ores have diminished, making low-grade ores inevitable. These low-grade iron ores need further

获取价格

(PDF) Beneficiation and Mineral Processing of Mineral

2017/3/7 temperatures as high as 1300 °C is used for the production of various grades of CCM. 2) Fused Magnesia (FM) is produced in athree phase Electric Arc Furnace.High grade magnesite or Caustic ...

获取价格

Ironsand - Wikipedia

Ironsand. Iron sand from Phoenix, Arizona, attracted to a magnet. Ironsand, also known as iron-sand or iron sand, is a type of sand with heavy concentrations of iron. It is

获取价格

Beneficiation of Fine Iron Ores using the Desand Process - AusIMM

The low-grade clay-rich -1.0 mm fraction of fine iron ores have often proved difficult to upgrade and capital intensive to process when using traditional wet beneficiation technology including single or two stage hydrocyclone desliming, wet high intensity magnetic separation (WHIMS), spirals and final dewatering using fine screens. Very fine (<0.010

获取价格

Beneficiation of Kulon Progo iron sand by using tabling and

DOI: 10.1063/1.5030246 Corpus ID: 139708907; Beneficiation of Kulon Progo iron sand by using tabling and magnetic separation methods @inproceedings{Oediyani2018BeneficiationOK, title={Beneficiation of Kulon Progo iron sand by using tabling and magnetic separation methods}, author={Soesaptri Oediyani

获取价格

Recent process developments in beneficiation and metallurgy of

2024/4/1 Among beneficiation techniques, froth flotation is the most well-established technique to concentrate RE minerals and can process a wide range of fine particle sizes. Due to the difference in hydrophilicity between RE minerals and associated minerals, flotation reagents are added to achieve separation.

获取价格

Beneficiation Studies on Recovery of Secondary Sources of Iron

2009/9/1 Detailed beneficiation studies carried out by various techniques indicated that the iron content can be upgraded by simple low intensity wet magnetic separation after grinding the sample to below ...

获取价格

6 Methods for Removing Iron From Silica Sand Mining Pedia

2021/11/30 In the second stage of beneficiation, the silica sand is immersed in the culture solution at a temperature of 90 ℃, which can reduce the content of Fe₂O₃ in the silica sand to 0.012%, which is very suitable for the production of high-quality glass. 07

获取价格

Iron Ore Beneficiation Plant - JXSC Machinery - Mineral Processing

Iron ore beneficiation is mainly a process of separating valuable minerals and iron minerals from ores to extract high-quality iron ore. The iron ore process mainly includes crushing, grinding, washing, beneficiation, dewatering, etc. 1. Magnetite Beneficiation: The main iron mineral contained in magnetite is iron tetroxide (Fe3O4). And iron in ...

获取价格

Towards a Sustainable and Enhanced Iron Ore Recovery: Bio-beneficiation

2024/3/16 Iron ore is essential in steel making; however, high-grade ores have diminished, making low-grade ores inevitable. These low-grade iron ores need further beneficiation to upgrade the iron content. Currently, traditional physical and chemical methods are utilized and are not environmentally friendly. Bio-beneficiation techniques

获取价格

Quartz Beneficiation Plant Equipment - JXSC Machinery

1. Washing-classifying-desilting: In the quartz sand beneficiation process, the fine-grained grade with a particle size of less than 0.1 mm is usually called slime.For quartz sand with a large amount of clay and ore mud, as the particle size becomes finer, the grade of silica gradually decreases, while impurities such as iron and aluminum rise instead.

获取价格

Beneficiation of Iron Ores – IspatGuru

2014/4/3 Fig 2 Typical iron ore beneficiation process. Methods / techniques for iron ore processing. Scrubbing – Scrubbing is the process by which clays, slimes and any potential oxidization present in or on the ore are removed typically by using water. The conditioning of the ore surface is done by the scrubbing for further beneficiation.

获取价格

Modeling and Optimisation of Spiral Concentrator for Beneficiation

2020/7/23 Experiments were carried out using a spiral concentrator test rig containing feed conditioner, centrifugal pump and a spiral concentrator with feed to spiral and recirculation. Time samples of concentrate and tails were collected, weighed, dried analysed. Regression equations were developed for Concentrate yield, grade and

获取价格

Beneficiation Strategies for Removal of Silica and Alumina from

2021/11/24 As higher-grade ores become depleted, there will be a greater focus on developing suitable beneficiation strategies to treat low-grade hematite-goethite ores containing higher levels of impurities such as silica and alumina. The processes selected to reduce impurity levels of these lower-grade iron ores will depend on the ore mineralogy

获取价格

(PDF) Beneficiation and Mineral Processing of Mineral Sands

2017/3/7 Beneficiation and Mineral Processing of Mineral Sands, Sand and Silica Sand Processing Sand, Sand into Silicon-Silicon carbide ; Heavy Mineral Sand; Fumed silica ; Separation of Heavy Minerals ...

获取价格

Iron oxide contents in sand products after different beneficiation ...

Download scientific diagram Iron oxide contents in sand products after different beneficiation techniques from publication: Suzan S. Ibrahim, Ali Q. Selim, and Ayman A. Hagrass, “Gravity ...

获取价格

Existing and New Processes for Beneficiation of Indian Iron

2020/2/8 The iron ore industries of India are expected to bring new technologies to cater to the need of the tremendous increase in demand for quality ores for steel making. With the high-grade ores depleting very fast, the focus is on the beneficiation of low-grade resources. However, most of these ores do not respond well to the conventional

获取价格

Beneficiation Strategies for Removal of Silica and

2021/11/24 As higher-grade ores become depleted, there will be a greater focus on developing suitable beneficiation strategies to treat low-grade hematite-goethite ores containing higher levels of impurities such

获取价格

(PDF) Beneficiation and Mineral Processing of

2017/3/7 Beneficiation and Mineral Processing of Mineral Sands, Sand and Silica Sand Processing Sand, Sand into Silicon-Silicon carbide ; Heavy Mineral Sand; Fumed silica ; Separation of Heavy Minerals ...

获取价格

Iron oxide contents in sand products after different

Download scientific diagram Iron oxide contents in sand products after different beneficiation techniques from publication: Suzan S. Ibrahim, Ali Q. Selim, and Ayman A. Hagrass, “Gravity ...

获取价格

Existing and New Processes for Beneficiation of Indian Iron

2020/2/8 The iron ore industries of India are expected to bring new technologies to cater to the need of the tremendous increase in demand for quality ores for steel making. With the high-grade ores depleting very fast, the focus is on the beneficiation of low-grade resources. However, most of these ores do not respond well to the conventional

获取价格

Dry beneficiation of iron ore - Mineral Processing

Dry beneficiation capacity will increase by around 110 Mta. An important role is being played by projects for iron ore concentrate extraction by means of dry magnetic separation (Fig. 16). Three projects with a total of 9.6 Mta are already in the construction phase, another project with 8.5 Mta capacity concerns the production of iron ore ...

获取价格

Iron ore beneficiation plant equipments manufacturers in India

We specialise in iron ore beneficiation plants, silica sand washing plant and more. We at Metofabrik offer equipment, services and process solutions to industries on turnkey basis, allowing our esteemed customers to focus on their core business. We also cater to fractional needs of mining and beneficiation equipments.

获取价格

A review of the beneficiation of rare earth element bearing

2013/2/1 Highlights Review conducted of RE mineral beneficiation using English and Chinese language sources. Of the 250 known RE minerals only bastnäsite, monazite and xenotime are extracted commercially. Flotation, using fatty acids or hydroxamates, is the primary separation process for RE minerals. Currently, optimal beneficiation processes

获取价格

Iron ore beneficiation: an overview - ScienceDirect

2023/1/1 Flow-sheets for low-grade ore processing of different iron ore mines vary significantly; however, the underlying principle of operation is very similar. Methodology for selection of beneficiation flowsheet is already defined in the above sections. For beneficiation of coarser fraction (+1 mm), jigging is widely used. However, in some

获取价格

How to Efficiently Remove Iron Impurities from Quartz Sand?

2023/7/16 Beneficiation is a method of separating valuable minerals and impurities from ores using physical or chemical means. In the beneficiation process of quartz sand, the separation of iron minerals ...

获取价格

Effect of iron ore tailings as partial replacement to fine ... - Springer

2023/12/13 After the beneficiation of iron ore, the waste is generated, which arise many environmental issues for both living and nonliving components. Iron ore tailings are a byproduct of the mining and processing of iron ore, and their potential use as a replacement resource is the emphasis of this study. The purpose of this research is to determine how

获取价格

Beneficiation of mineral sands: a practical outlook - ScienceDirect

2023/1/1 The material flow in the titanium industry is shown in Fig. 5.1.The ilmenite of <58% TiO 2 can be used for producing TiO 2 slag or TiO 2 pigment through the sulfate route The TiO 2 content will largely determine the relative values of titaniferous feedstocks, and the more TiO 2 there is in the material the greater its value. For comparison, the value of

获取价格

Silica Sand Processing Plant - JXSC Machinery

Silica sand beneficiation mainly includes crushing, washing, classifying, magnetic separation, flotation, etc, to remove small or trace impurities in silica sand. We supports customized silica sand washing plant solutions according to mineral composition and customer requirements. Crushing Grinding: The original silica sand ore is crushed and

获取价格

Coal beneficiation: theory and practice - ScienceDirect

2023/1/1 Typical results in a coal beneficiation plant using spirals to treat fine coal indicated very little deterioration in performance with the under-slimed and deslimed feed material (−500 mesh) even when the feed contained ~50% of −500 mesh material. However, the clean coal ash reduced when the −500 mesh material was removed.

获取价格

Beneficiation - an overview ScienceDirect Topics

Mineral Processing. Swapan Kumar Haldar, in Mineral Exploration (Second Edition), 2018. 13.2.4.3 In-Stream Analyzer and Process Control. Mineral beneficiation, particularly base and noble metals, is sensitive to optimum use of reagents, recovery of metals, and clean concentrate.High fluctuation of feed grade at flotation cells yields loss of metals to tailing.

获取价格تاسیس دستگاه آسیاب توپ

تكلفة كسارات فكية صغيرة عمان

مصنع غسيل محمول لتعدين الذهب

السعري كسارة الحجر 400 × 600

سعر كسارة الحجر الصغيرة في العراق

كسارة شاشة العداد

كسارات بعجلات الصين

تفاصيل مطاحن عاء

التعدين تحت الأرض في إندونيسيا

بروتوكول لتخليق جزيئات أكسيد الألومنيوم النانوية بطريقة طحن الكرة

الات الصناعيت المسا مير مستعملة في الجزائر

بينشتوب الثلاثي لفة مطحنة طحن مطحنة الصين

خطة شبكة الاتصالات العالمية of36x30 محطة كسارة الحجر

أفضل آلة كسارة فكية كوارتز السيليكا في الهند

cme شركات تصنيع كسارة متنقلة

آلة غانا

تكلفة مشروع مطحنة دال صغيرة

اجهزة بناء العضلات

جمعية كسارة الحجر دولة كارناتاكا

excavation equipment for feldspar mining

تستخدم كسارة الدولوميت كسارة الفك السعودية

البوتاسيوم الفلسبار طحن شمشون

مصنع الكسارة في باكستان في لاهور

آلة محطم سعر الكسارة

500 تخطيط الهيدروكربونات النفطية الكرة

بيع كسارات الحجر الأوروبي المستعملة

حول لدينا

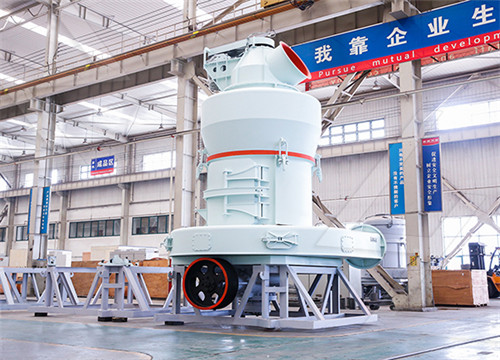

تأسست شركة Henan Lrate للعلوم والتكنولوجيا المحدودة التي تصنع معدات التكسير والطحن الكبيرة والمتوسطة الحجم في عام 1987. وهي شركة مساهمة حديثة مع البحث والتصنيع والمبيعات معًا.

على مدار أكثر من 30 عامًا ، تلتزم شركتنا بنظام الإدارة العلمية الحديث والتصنيع الدقيق والريادة والابتكار. الآن أصبحت LIMING رائدة في صناعة تصنيع الآلات المحلية والخارجية.

2021/07/20

2021/07/20